Materials, Equipment and Compliance Management

The QR code linked, digital asset platform from Mobtag is designed with simplicity in mind, allowing users to tailor the system to suit their business, processes and clients needs. Customize asset fields and layouts, digitalize your forms with flexible options, and manage stock with dedicated QR codes for stock in/out tracking. Challenge us to implement the system to optimise the benefits, or feel free to register and start the process yourself today.

Example Applications

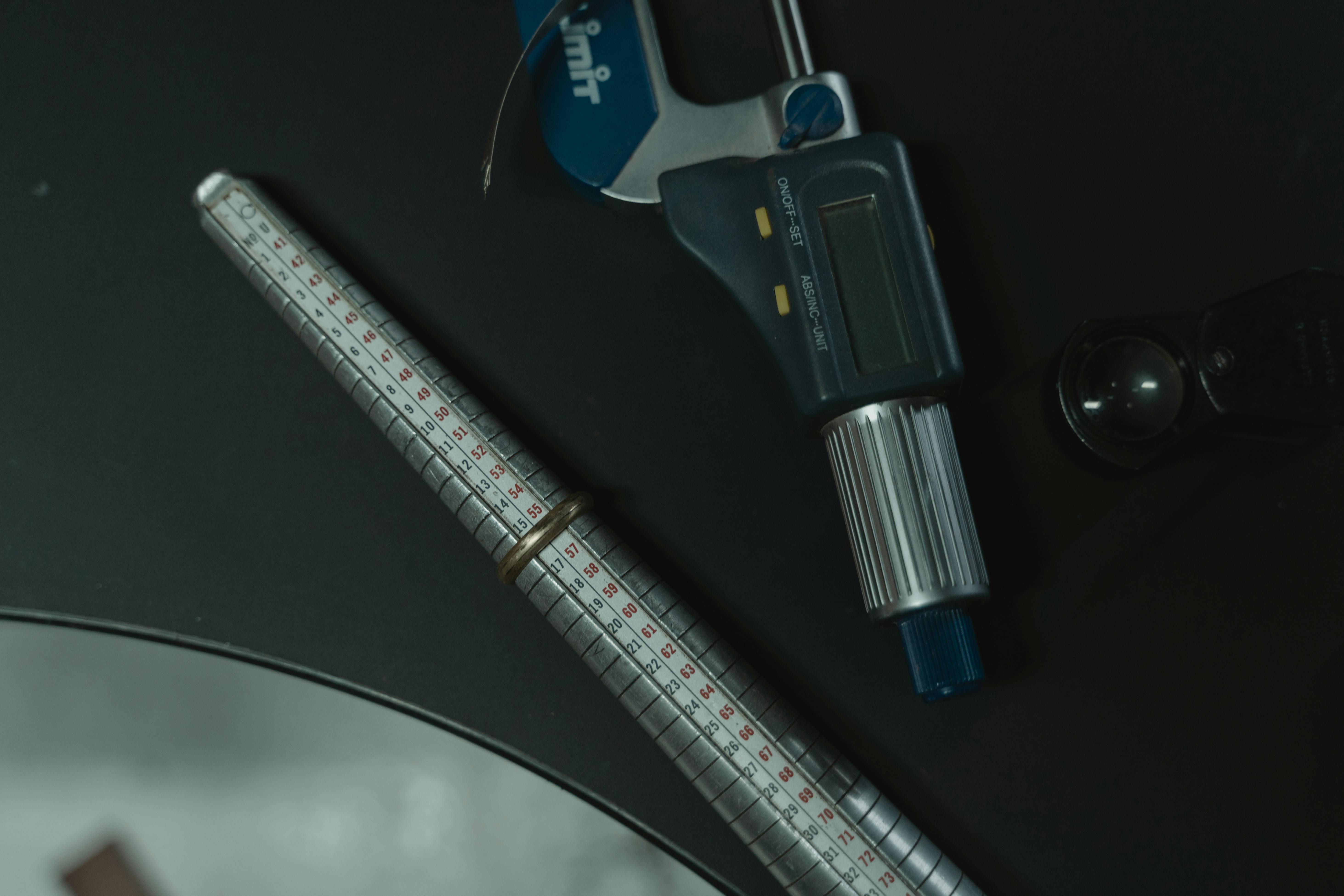

Calibration Management

Track calibration records, schedules, and certificates with QR tag integration for instant access to equipment history.

Lifting Equipment

Manage inspection schedules, compliance records, and safety documentation for all lifting equipment and rigging gear.

PAT Testing

Streamline portable appliance testing with digital records, automated reminders, and instant certificate generation.

Hire Equipment

Track rental equipment, manage bookings, monitor locations, and ensure timely returns with real-time status updates.

Hose Management

Control hydraulic hose testing, maintenance schedules, and pressure test records with complete traceability.

Materials Management

Organize inventory, track material certificates, and maintain complete documentation for ISO9001 compliance.

Case Studies

MGH

MGH partnered with Mobtag to streamline their asset management and compliance processes. Facing challenges with outdated tracking systems and manual documentation, they needed a flexible, digital-first solution that could integrate seamlessly with their existing workflows.

ESSCO group

The ESSCO Group approached Mobtag to improve oversight across multiple sites and ensure consistent asset tracking company-wide. Their previous system made it difficult to monitor equipment use and maintenance schedules across departments, leading to delays and compliance risks.

Sunnerg

Sunnerg needed a simple, scalable way to manage inspection records and maintenance logs across a growing number of client sites. Their paper-based systems were prone to delays, missed updates, and human error.